Email:Alisa@lantianmachine.com

Factory outlet

Factory outlet Quality Assurance

Quality Assurance Worry free delivery

Worry free delivery After sales guarantee

After sales guarantee

Product Introduction:

At present, 70% of large discarded furniture in various places are made of artificial boards such as fiberboard, springs, nails, particleboard, and joinery board. They can be reused as second-hand furniture. If we use large garbage sorting machine to crush the materials, the crushed materials will be screened, and the scrap iron can be classified for re-smelting, and the wood, waste cloth, and sponge can be sent to biomass power plants for combustion. Therefore, the recycling value of large garbage becomes greater after being dismantled.

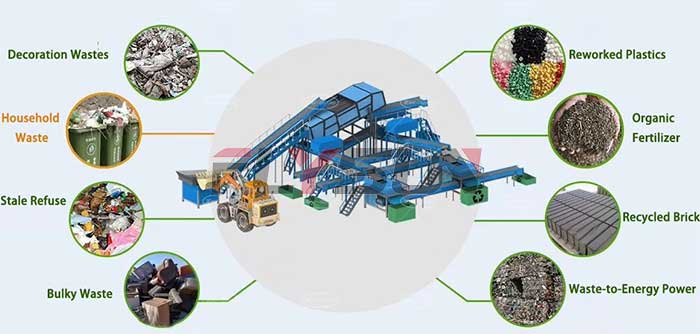

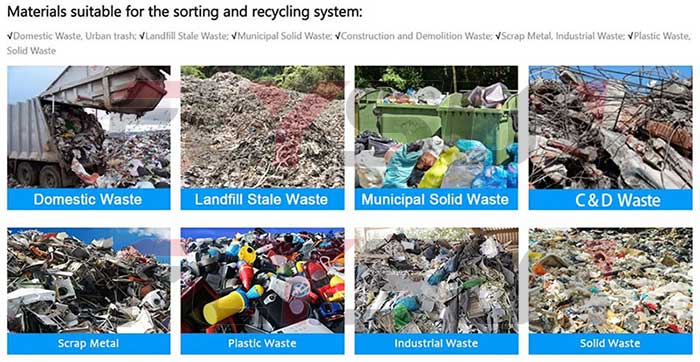

Application scope

Working principle of large garbage screening machine

Large garbage treatment machine is a kind of garbage treatment equipment integrating mechanization, automation and intelligence. Its working principle is mainly based on physical sorting technology. Through crushing, screening, magnetic separation, wind separation and other means, recyclable materials (such as metal, wood, plastic, etc.) and non-recyclable materials (such as fabric, glass fragments, etc.) in large-scale garbage are effectively separated.

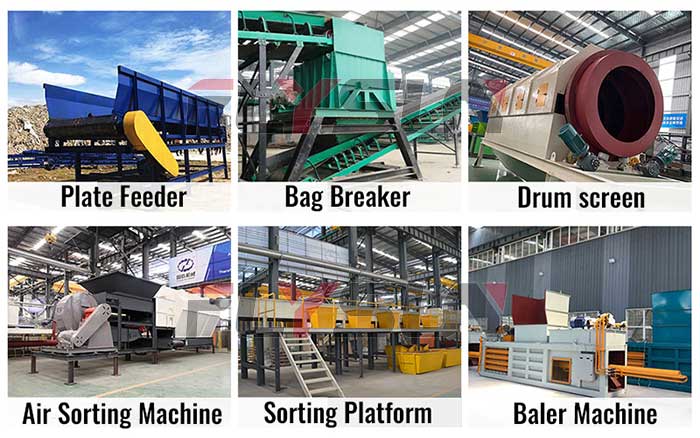

Supporting Equipment

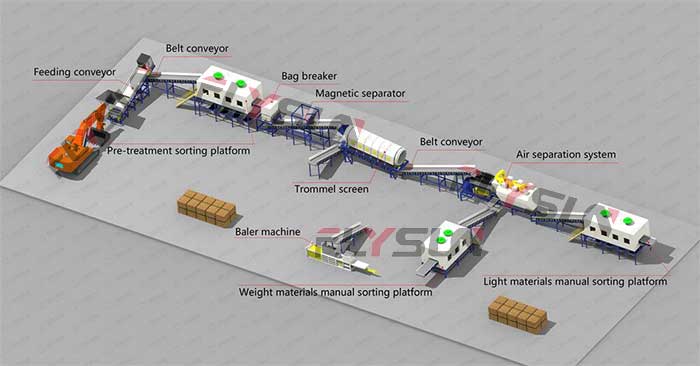

Production line process

large garbage sorting machine process

Crushing stage: First, large pieces of garbage are sent to the crusher for preliminary crushing to reduce the volume for subsequent processing.

Screening stage: The crushed materials are graded by vibrating screen or drum screen, and particles of different sizes are separated into different collection areas.

Magnetic separation stage: Use strong magnetic fields to attract ferromagnetic materials (such as iron, nickel, cobalt, etc.) to achieve preliminary separation of metals and non-metals.

Wind selection stage: By adjusting the air flow speed and direction and taking advantage of the difference in material density, light materials (such as plastics and paper) and heavy materials (such as glass and stones) are further separated.

Manual assisted sorting: For some complex or difficult to automatically identify materials, manual sorting is also required to ensure sorting accuracy.

Customer Case

Singapore Customer Case

Türkiye Customer Case

Delivery site

The application of msw sorting equipment not only improves the efficiency and quality of solid waste treatment, but also brings significant economic and environmental benefits to the city. Through automatic sorting, the resources in solid waste can be recycled to a large extent and resource waste can be reduced; at the same time, the automatic sorting production line reduces manpower input and energy consumption, and reduces the cost of solid waste treatment. In addition, by reducing the emission of harmful substances and the accumulation of general garbage, the automatic sorting production line has also greatly improved the urban environment and improved the quality of life of residents.

Qualifications

We are always focusing on developing new equipment to help our customers improve their productivity. Our fully automatic bulky waste handlers are suitable for a variety of waste types, helping customers complete the work faster and recover more reusable waste resources.

Provide you with a better product experience

Reply immediately within 30 seconds of consultation

Address:

No. 9 Yulian Industrial Agglomeration Zone, Zhanjie Town, Gongyi City, Zhengzhou City, Henan Province

Consult:

Get quote

Email:

Alisa@lantianmachine.com