Email:Alisa@lantianmachine.com

Factory outlet

Factory outlet Quality Assurance

Quality Assurance Worry free delivery

Worry free delivery After sales guarantee

After sales guarantee

Product Introduction:

The operation mechanism of the waste wood crusher machine covers multiple functions such as shearing, shredding and compression to achieve effective reduction of material volume. After several years of scientific research and field application, the equipment has undergone continuous improvement and innovation based on the specific actual needs of my country, and launched a series of waste wood crusher equipment with exquisite technology and advanced design concepts, providing reliable hardware support for the early shredding and volume reduction of my country's waste resources.

Internal structure

The equipment can be used in a wide range of applications, including but not limited to large volumes of waste such as wood, wood chips, wooden pallets, logs, branches, paint buckets, and casings of old household appliances (whether made of plastic or metal).

Widely used

waste wood shredder machine structural features:

In terms of structural design, the waste wood crusher machine demonstrates a high degree of versatility and versatility. It adopts a standardized modular design concept to ensure good interchangeability between parts. For the cutting blades, the auxiliary blades are made of die forging technology, while the main blades are made of special alloy steel and are processed by a specific process, thus having excellent wear resistance and high strength. The transmission part cleverly uses the transmission method of the intermediate gear to form a differential effect. In addition, the device also has the characteristics of an easily removable screen, a beautiful appearance, and a precise and compact structure.

In terms of performance, the equipment has the following significant advantages:

1. It can handle large-volume waste that single-shaft crushers cannot handle, such as large objects, baskets, pipes, plates, wood, tires, scrap metal barrels, and large rolls of film.

2. Its frame is made of extra-thick plates for precision processing, equipped with a large-angle hexagonal column shaft and a large-diameter three-dimensional feed hopper to ensure the safe input of large pieces of raw materials.

3. The rotary blades are uniquely designed and processed in terms of thickness, shape and arrangement order, so that they have strong shear force, sharp blades and high crushing efficiency.

4. The lower speed during operation generates less noise and less dust emission.

5. The cutting blades are made of special alloy steel, so they have excellent durability.

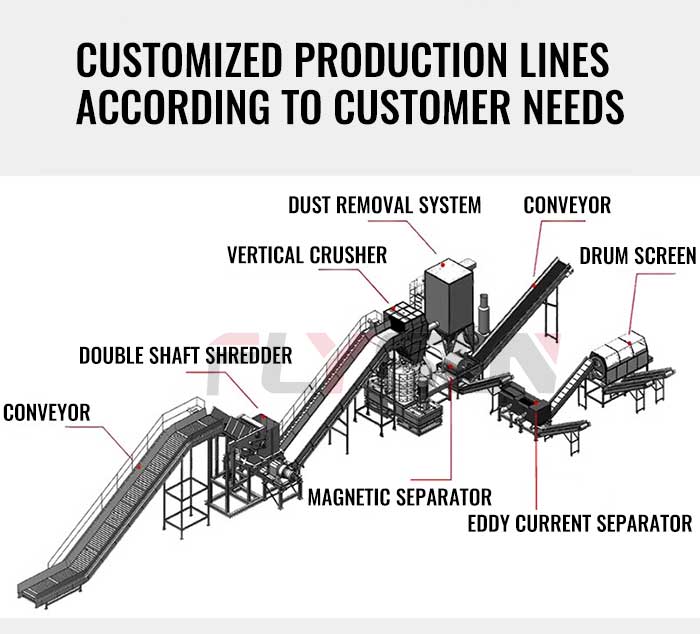

Double shaft shredder solution

We can provide different types of blades for selection according to the different materials to be processed. The waste wood crusher machine adopts a design of double-axis blades cutting each other to meet the needs of different crushing materials. The size of the crushed material mainly depends on the thickness of the crushing blade and the number of teeth. The thinner the blade, the smaller the size of the crushed material; the more teeth, the shorter the length of the crushed material; and the thicker the blade, the harder the material that can be torn.

Customer Case

Myanmar customer site

Vietnam customer site

Delivery site

Packaging

In terms of packaging, we provide two options: inner packaging and outer packaging. Inner packaging is usually made of plastic and paper to protect key components such as motors; outer packaging is usually made of wooden boxes or containers to ensure the safety of the equipment during transportation. In addition, we can also customize the packaging according to the actual needs of customers.

In terms of delivery, we mainly use sea transportation. At the same time, we will ensure that the product quality meets the standards and deliver on time according to the agreed time.

Our Honor

In order to ensure that customers can use our waste wood crusher equipment without worries, we hereby make the following commitments:

1. We will strictly select high-quality materials to ensure the reliability of the equipment.

2. Whether in material selection or production process, we will strictly follow the ISO9001 standard and conduct quality control through comprehensive inspections.

3. We will provide customers with professional technical support and after-sales service.

4. We will provide customers with product upgrade information in a timely manner.

Customer photo

Henan Fangxin Machinery Manufacturing Co., Ltd. was established in 2011. It is a joint-stock enterprise focusing on the research and development, production and sales of waste resource sorting and recycling equipment. The company has many professional subsidiaries, and its products cover many fields such as waste wood shredder machine, domestic waste sorting equipment, urban solid waste treatment equipment, waste metal material recycling equipment and large waste crushing equipment. If you have any needs or questions, please feel free to contact us.

Provide you with a better product experience

Reply immediately within 30 seconds of consultation

Address:

No. 9 Yulian Industrial Agglomeration Zone, Zhanjie Town, Gongyi City, Zhengzhou City, Henan Province

Consult:

Get quote

Email:

Alisa@lantianmachine.com