Email:Alisa@lantianmachine.com

Factory outlet

Factory outlet Quality Assurance

Quality Assurance Worry free delivery

Worry free delivery After sales guarantee

After sales guarantee

Product Introduction:

coconut shell shredder machine can effectively reduce the size of materials by shearing, tearing and squeezing. The equipment has a high degree of automation and excellent production efficiency, allowing users to process large coconuts economically and efficiently. After years of research and practice, the coconut waste shredder machine produced by our company has been continuously improved and developed in combination with the actual domestic situation, and a series of models with mature technology and advanced design have been launched. These equipment provide reliable quality solutions for the early crushing and volume reduction treatment in waste recycling.

Working principle

Widely used

Product advantages:

The coconut shell crusher machine is exquisitely designed and compact, and is particularly suitable for processing small, low-hardness and portable materials.

Its features include:

1. Equipped with a dual motor and dual reducer transmission system to ensure high torque at low speed, thereby enhancing the shredding ability;

2. The cutter is made of high-alloy steel imported from Germany, which is not only wear-resistant but also has a long service life;

3. The main shaft is made of 42CrMo high-alloy steel, which has excellent mechanical strength and good impact resistance after precision processing;

4. Fixed blades are installed on both sides of the knife box to effectively prevent material entanglement, and these parts can be disassembled separately for easy daily maintenance;

5. The use of spherical roller bearings and the implementation of four-layer sealing measures can effectively block dust and moisture intrusion;

6. The integrated PLC control system provides current monitoring function and overload protection mechanism, and can automatically reverse the operation when abnormal conditions are detected to protect the motor and cutter from damage;

7. The overall structure is compact and reasonable, and occupies less space;

8. The equipment has a long service life and relatively low maintenance cost.

Internal structure

coconut shell shredder machine structure:

1. Crusher body: The body is made of high-quality plates through precision welding technology to ensure that the equipment can maintain stable operation when subjected to long-term heavy-load operations.

2. Bearing/seal design: The bearing seat adopts a split and detachable structure design, so that key components such as the moving knife, fixed knife and bearing can be quickly disassembled and assembled, greatly simplifying the maintenance process and facilitating tool replacement. Its sealing system effectively isolates the crushed materials from grease, and can protect internal parts such as bearings and gears from damage even when handling liquid substances.

3. Moving/fixed knife characteristics: It is forged with alloy tool steel as the raw material. After multiple fine processing processes and special low-temperature freezing heat treatment technology, it not only enhances the cutting efficiency of the tool, but also significantly extends its service life.

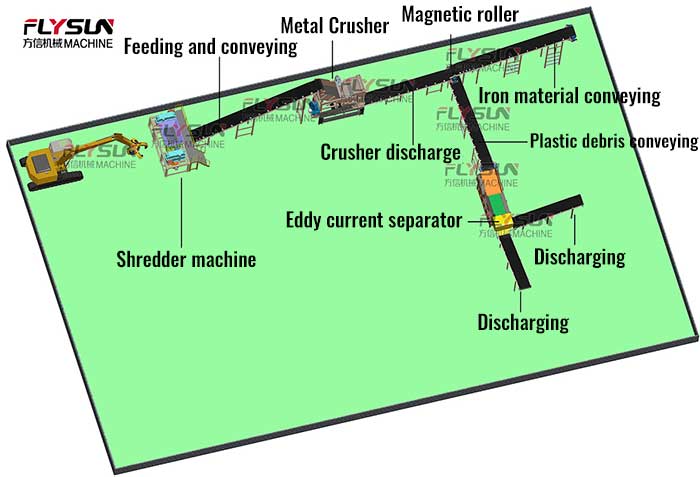

Production line flow chart

coconut waste shredder machine Application areas:

1. Various hollow containers: including plastic beverage cans, plastic barrels, iron barrels, packaging boxes and packaging barrels.

2. Waste electrical appliances: covering TV sets, washing machines, refrigerator shells, etc.

3. Pipes: involving large pipes, pipe fittings and PE pipes.

4. Waste templates: including wooden pallets, plastic pallets and forklift pallets.

5. Second-hand tires: both car tires and truck tires are included.

6. Waste metal: car shells, aluminum alloy materials, waste aluminum parts, engine shells, lead and steel plates with a thickness of no more than 5 mm. In addition, it also handles a variety of wastes such as kitchen waste, domestic waste, animal carcasses, RDF derivatives, medical waste, bio-orange sticks, garden waste, waste furniture, old clothes and electronic waste.

Customer Case

Myanmar customer site

Vietnam customer site

Delivery site

Packaging

Inner packing:motors are usually packaged in plastic and paper.

Outer packing :usually wooden case or the container.

We can also pack the machine according to the client's need.

Delivery

Delivery method:by sea.

Delivery time:We will confirm the quality of the products and deliver them on time as agreed.

Our Honor

In order to ensure that customers can use our coconut shell crusher machine without worries, we solemnly promise:

1. We insist on using high-quality materials to ensure the reliability and durability of the product.

2. From the procurement of raw materials to the delivery of finished products, we strictly abide by the ISO9001 international quality management system standards and strictly monitor through a comprehensive quality control process. 3. We provide a full range of technical support and professional guidance services to help solve any problems you encounter during use.

4. We will push the latest product upgrade information and related information to you in a timely manner, so that you can always grasp the most cutting-edge technology trends.

Customer photo

Henan Fangxin Machinery Manufacturing Co., Ltd. has been committed to the research, development, production and sales of waste resource sorting, processing and recycling equipment since its establishment in 2011. As a joint-stock enterprise, we own a number of professional companies with a wide range of products, including coconut shell shredder machine, domestic garbage sorting equipment, urban solid waste treatment equipment, scrap metal material recycling equipment and large garbage crushing equipment. If you have any needs or questions, please feel free to contact us and we will serve you wholeheartedly.

Provide you with a better product experience

Reply immediately within 30 seconds of consultation

Address:

No. 9 Yulian Industrial Agglomeration Zone, Zhanjie Town, Gongyi City, Zhengzhou City, Henan Province

Consult:

Get quote

Email:

Alisa@lantianmachine.com