Email:Alisa@lantianmachine.com

Factory outlet

Factory outlet Quality Assurance

Quality Assurance Worry free delivery

Worry free delivery After sales guarantee

After sales guarantee

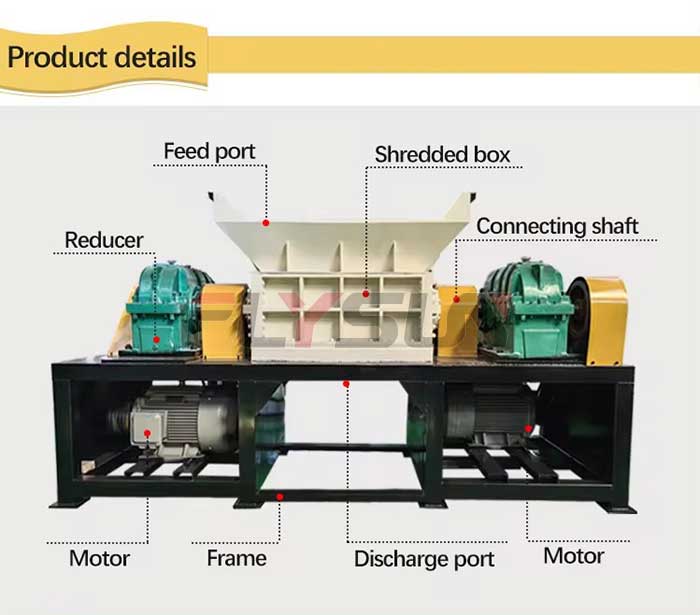

Product Introduction:

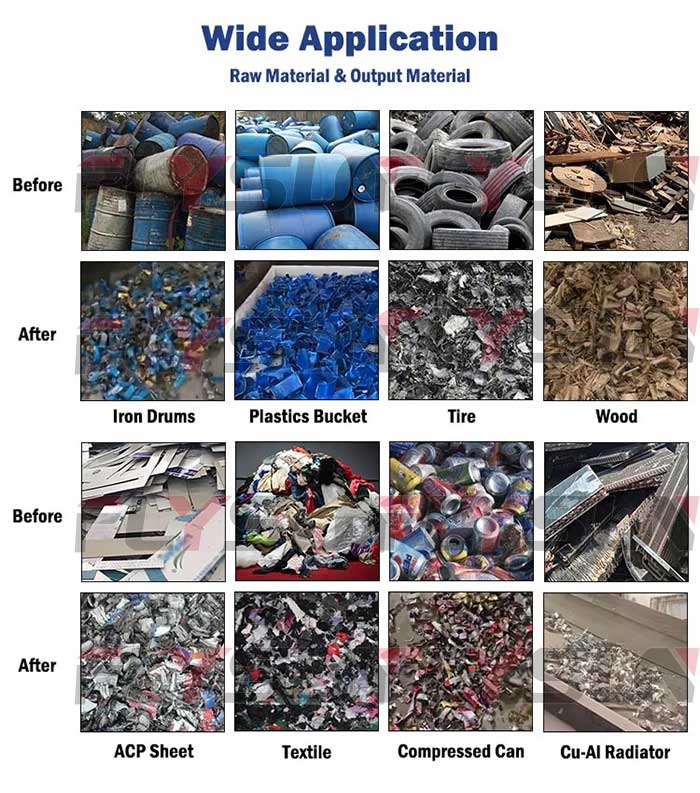

The plastic barrel shredder is a powerful assistant in the solid waste treatment industry and is suitable for the recycling of various waste materials. Whether it is heavy, difficult to shred or bulky materials, such as waste household appliances, metals, rubber tires, packaging barrels, large blue barrels and waste cars, it can easily handle them. Its wide applicability and practicality allow the shredded materials to be further refined and processed to meet the needs of different industries. As a primary shredding equipment, the plastic barrel shredder machine plays an important role in many industries such as industrial waste recycling, garbage disposal, electronic manufacturing, wood processing, domestic waste recycling, plastic recycling, tire recycling and papermaking. The equipment has the characteristics of low speed, high torque and low noise. It adopts Siemens programming control system to realize automatic control and has start, stop, reverse and overload automatic reverse control functions to ensure easy operation, safety and reliability.

Internal structure

Depending on the product we use, users can choose different blades to meet specific needs. The plastic barrel crusher machine uses a dual-axis blade that cuts each other to ensure that the material is effectively shredded. The size of the shredded material is mainly determined by the thickness of the blade and the number of teeth. Specifically, the thinner the blade, the smaller the size of the shredded material; and the more teeth the blade has, the shorter the length of the shredded material. In addition, the thickness of the blade will also affect the hardness of the material it can handle. The thicker the blade, the harder the material it can shred.

Application scope

The plastic barrel shredder fully adopts the advanced microcomputer automatic control system, integrating the control functions of start, stop, reverse and overload automatic reverse, showing the excellent performance of low speed, high torque and low noise. Its bearing seat is designed as a split structure, which greatly facilitates the removal and replacement of the blade, and is particularly suitable for processing extra large, extra thick and difficult to shred materials.

Product advantages:

1. The thickness options of shredder blades include 15mm, 20mm, 40mm, 50mm, 75mm and 100mm. Users can choose the most suitable blade specifications according to the type of material to be processed and the size of the particles after crushing.

2. The use of shredders can significantly reduce the volume of recycled waste, thereby simplifying the transportation process of garbage.

3. The pricing of shredders mainly depends on their manufacturing materials and production efficiency. Different materials and blade configurations will lead to price differences.

Customer Case

Philippines Customer Case

Taiwan Customer Case

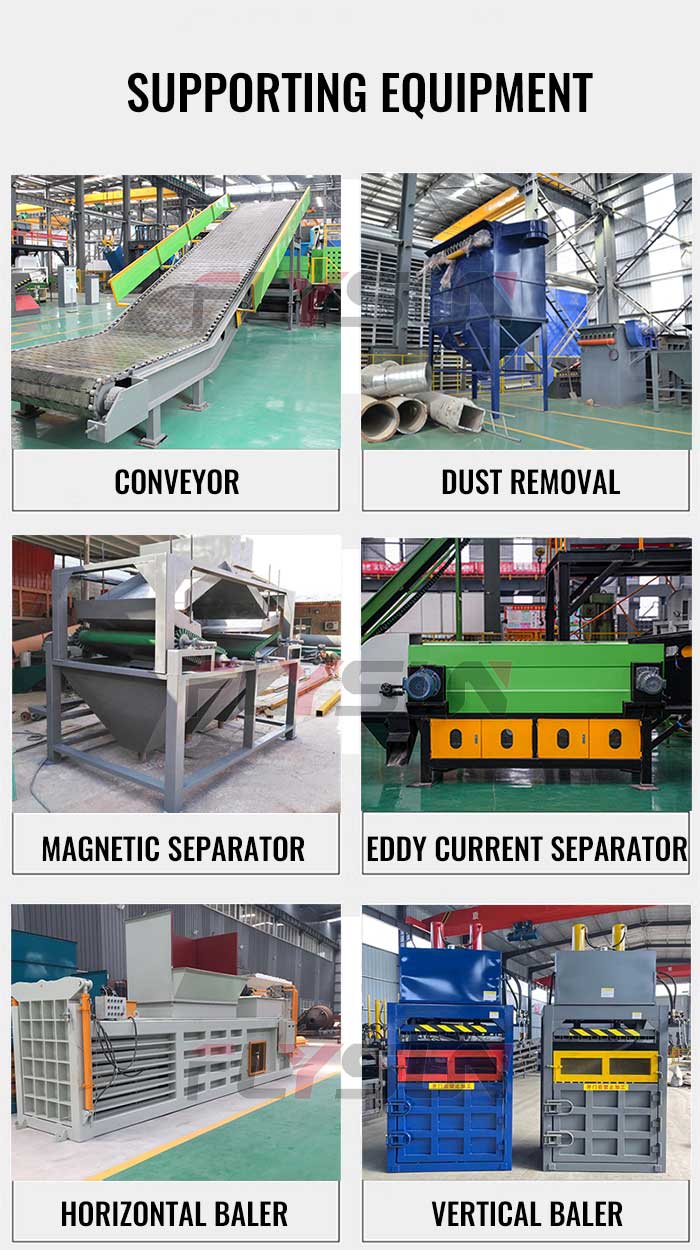

We are always committed to innovative equipment design, aiming to provide our customers with more efficient production solutions. Introducing our plastic barrel shredder machine, a fully automatic production line suitable for all kinds of waste, which can not only speed up your workflow, but also improve the recycling rate of waste resources and promote resource recycling.

Delivery site

Packaging and Delivery

We provide suitable packaging solutions according to the order quantity of the goods to ensure that they will not be damaged during transportation.

The packaging can be: plywood box, steel frame box, iron pallet and so on.

Certificate

Customer photo

Since its establishment in 2011, Henan Fangxin Machinery Manufacturing Co., Ltd. has been focusing on the supply of equipment for recycling solid waste, domestic waste, metal waste, construction waste, obsolete waste and landfill waste. The company adheres to the principles of customer first, machine quality first and employee first, and is committed to providing high-quality products and services. Our factory has a highly qualified workforce, 60% of whom have college degree or above. This provides a solid technical guarantee and innovation capability for our products. Our products have been exported to more than 60 countries around the world, including the United States, Europe, Russia, India, Brazil, Nigeria, etc. These successful cases fully demonstrate the quality and competitiveness of our products.

Our services include:

1) Strict quality control: We always adhere to quality-oriented and ensure that every product can meet the needs of customers.

2) Competitive prices: We provide customers with the most competitive prices by optimizing production processes and improving efficiency.

3) Advanced technology products: We continue to develop new technologies and launch new products to meet the ever-changing and needs of the market.

4) Smooth communication: We attach importance to communication with customers and keep abreast of customer needs and feedback in a timely manner in order to provide better services.

5) Effective OEM and ODM services: We can provide customized products and services according to customer needs.

Provide you with a better product experience

Reply immediately within 30 seconds of consultation

Address:

No. 9 Yulian Industrial Agglomeration Zone, Zhanjie Town, Gongyi City, Zhengzhou City, Henan Province

Consult:

Get quote

Email:

Alisa@lantianmachine.com